Capabilities

Accord has designed, produced and assembled thousands of finished marine products ranging from stainless-steel diving helmets, titanium valves, locking collars and marine made of brass, bronze, titanium and plastics.

Track Record

Accord has decades of marine manufacturing experience for multiple global OEMs and is famous for successfully mass producing one of the world’s first stainless-steel diving helmets following an intensive 5-year R&D process and design engagement for a global customer.

Certification

Accord maintains several industry certifications critical to the needs of the marine manufacturing industry, including ISO and market-specific certification and quality standards. This allows Accord to manufacture highly specialised, complex and tight tolerance components and finished products.

Accord maintains a major focus on serving the marine & commercial diving industry across the design, manufacturing and assembly of highly specialised, complex and tight tolerance components and products to meet international safety standards. This is supported by 40+ years of manufacturing experience and extensive R&D undertakings across the sector.

Marine and commercial diving components are notoriously challenging to produce due to the extreme machining and finishing requirements, international quality standards and lead times associated with the manufacturing and casting processes.

Over decades of serving the industry, Accord has developed a number of innovative, in-house production techniques and capabilities extending across standard operating procedures, temperature controls, investment castings, ceramics and wax moulding to more than meet this challenge. This is supported by the fact that Accord was one of the first manufacturers in the world to produce a stainless-steel diving helmet containing multiple high-precision components and hundreds of input materials for a global OEM.

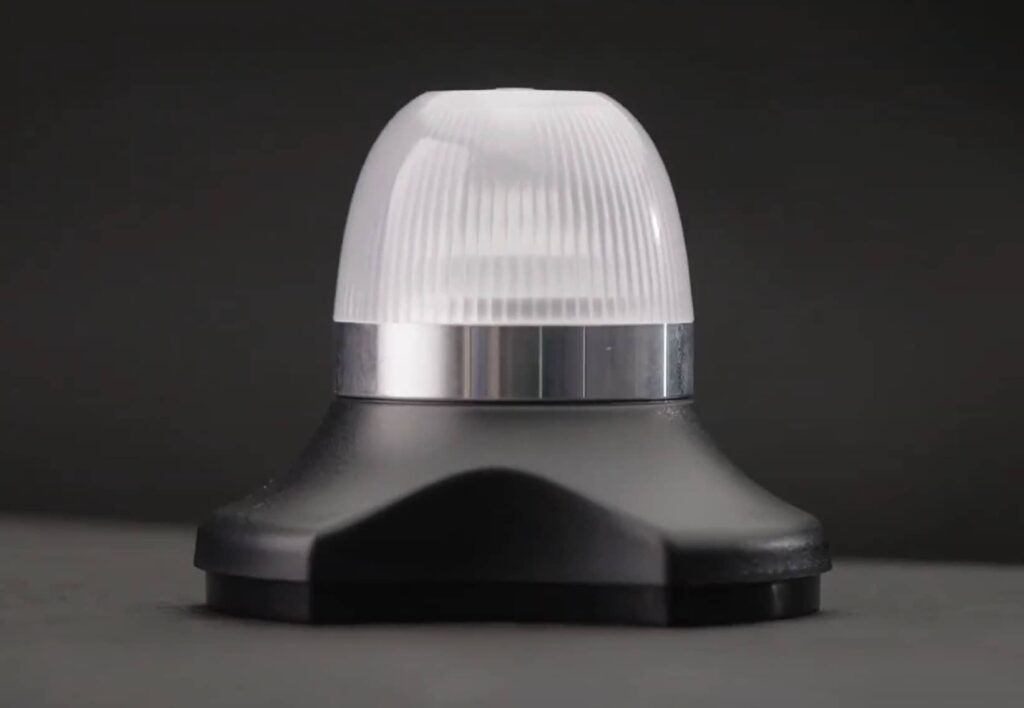

Accord has designed, produced and assembled thousands of finished products for the marine and commercial diving industry. This extends to stainless-steel diving helmets, titanium reclaim valves, oxygen regulators, breathing apparatuses, locking collars, marine accessories, brass and bronze helmets and much, much more.

We operate on a project-by-project basis, and work collaboratively with our clients on all design engagements. All project files, scope documents and design details are available online, providing customers with a ‘live’ feed to monitor project progress and comment freely.

We take preliminary concepts from 2D drawings or 3D models through an iterative design process, selecting the appropriate design software and project management methodology to drive the engagement.

All products must then go through a rigorous testing cycle before the final prototyping and validation phase. Only when the finished product is perfect, all items agreed in our initial scope assessment are complete and all parties are happy can final designs be signed off.

At Accord, the quality of our products are our greatest priority.