Accord designs, manufactures and assembles millions of high-value speciality products, including award winning medical-grade products, architectural hardware used in global hotels and speciality metals and alloys which are sold in more than 140 countries worldwide.

Indepth Materials knowledge

Accord decades of experience working with complex input materials used in the manufacturing process, including several Accord-specific trade secrets pertinent to unique metals, plastics and alloys.

Accord is able to meet customer-specific requirements to manufacture the highest quality products. Our customers often rely on our capabilities to help them create high-value bespoke products and parts.

Specialty goods are usually custom parts or products that require short manufacturing runs, but are high value production. These parts require the utmost attention to quality as it involves hard to manufacture materials and processes. Backed by our ISO quality standards and capabilities, we have full confidence to help our customers design and manufacture the best products possible.

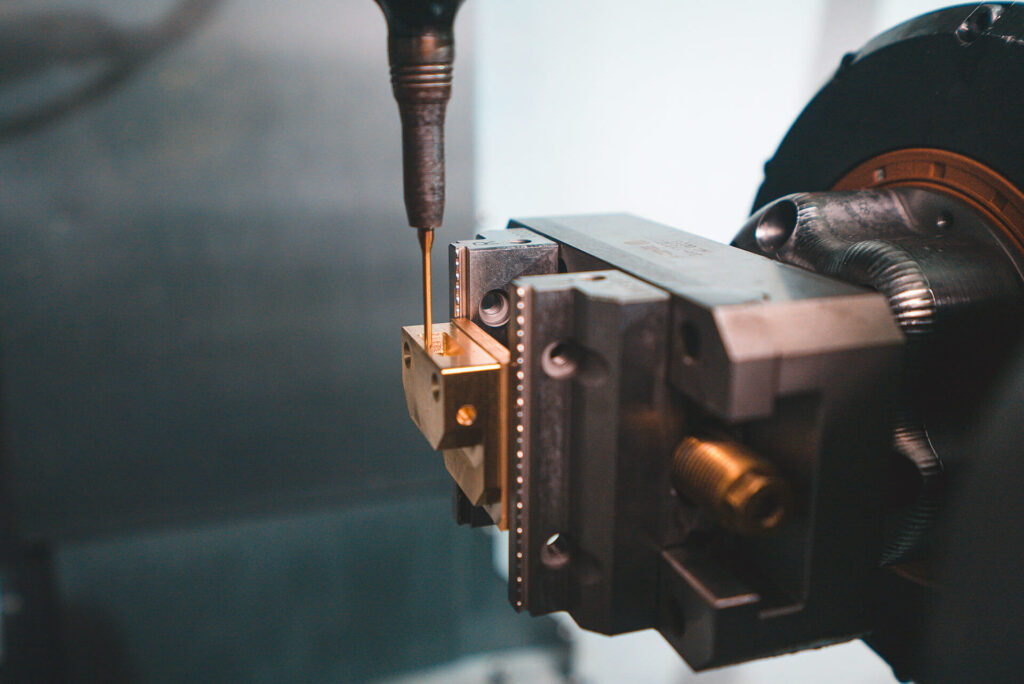

Specialty products usually require hard to manufacture metals such as aluminium, bronze, titanium and more. With our accumulated experience with such materials, we are able to give customers the best results when it comes to production with specialty metals.

We are able to meet larger volume requirements via the use of high output machines and process controls while being able to adhere to the high level of quality needed when making bespoke products and components.

Accord enjoys the challenge of manufacturing difficult, quality-critical products. Over the years we have manufactured products such as security locks, valves, machined aluminium modems and complex bearings where there is no room for compromise and tight tolerances are required. Accord has been able to maintain competitiveness in this area due to our competency in manufacturing high quality products and quality perspective where we measure tolerances within single digit microns where required.

We operate on a project-by-project basis, and work collaboratively with our clients on all design engagements. All project files, scope documents and design details are available online, providing customers with a ‘live’ feed to monitor project progress and comment freely.

We take preliminary concepts from 2D drawings or 3D models through an iterative design process, selecting the appropriate design software and project management methodology to drive the engagement.

All products must then go through a rigorous testing cycle before the final prototyping and validation phase. Only when the finished product is perfect, all items agreed in our initial scope assessment are complete and all parties are happy can final designs be signed off.

At Accord, the quality of our products are our greatest priority.